1) Purchase & Quality : Evaluation of quality competitiveness of partner companies

2) Environmental safety : On-site inspection of 22 provisions using RBA* standards (9 essential items: fire extinguishing equipment, hazardous materials and waste, wastewater facilities, etc.)

3) Labor human rights : On-site inspection of 19 provisions using RBA standards (8 essential items: prohibition of forced labor, prohibition of child labor, compliance with working hour regulations, accurate wage calculation/payment, provision of pay stubs/prohibition of delayed wages, withholding tax such as social insurance premiums payment, prohibition of inhumane treatment, prohibition of discrimination based on personal characteristics)

4) Financial status : Evaluate the credit rating and financial status of partner companies in consultation with an external professional agency

*Responsible Business Alliance (RBA) is an industry alliance dedicated to social responsibility in the global supply chain.

The basic transaction contract signed with partner companies includes human rights and labor standards

commonly used in the international community,

workplace safety standards set by NItus, and social responsibility (compliance with the code of conduct, etc.).

1. Establishment of a fair trade culture

– Fair trade agreement

2. Formation of trust relationship

– Listening to and resolving difficulties

– Creating a culture of shared growth

3. Strengthening the competitiveness of partners

-Delivery price 100% cash/cash equivalent payment

-Holiday delivery early payment

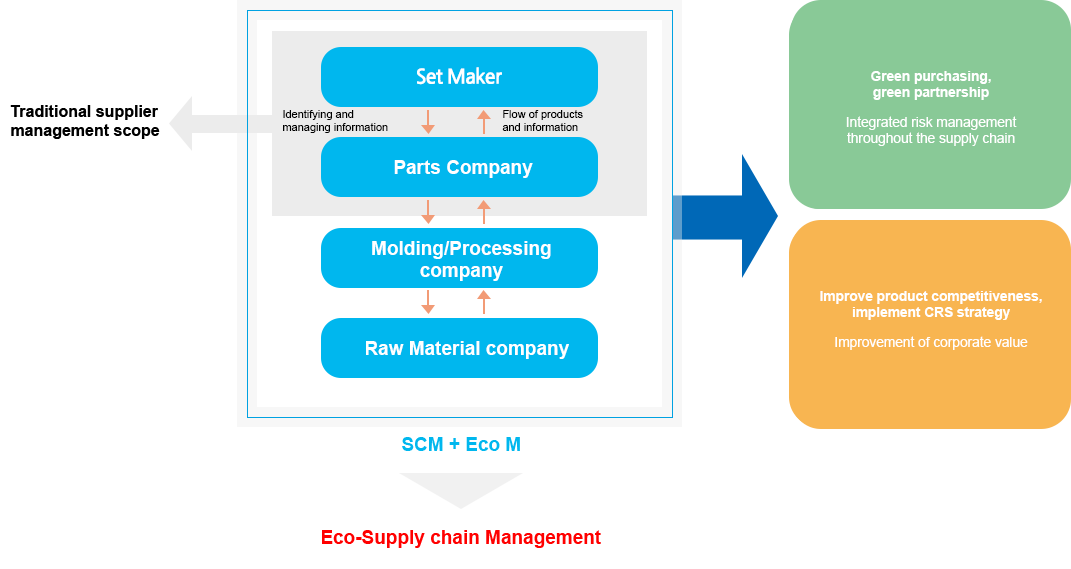

1. Reduce environmental impact

– Sharing information on carbon reduction facility support

– Promoting the use of renewable energy

2. Chemical substance management

– Conduct on-site investigation to ensure that safe working conditions are met and discuss ways to improve the handling procedures and control system of regulated substances

1. Responsible Mineral Purchasing Policy

– Efforts to proactively identify and alleviate social issues that arise when mining minerals in conflict areas and countries

2. Hazardous area management target

– Identifying and managing potential risks within the supplier company

– Creating a culture of shared growth

3.Complaint Handling/Objection Procedures

– Listening to diverse opinions from stakeholders

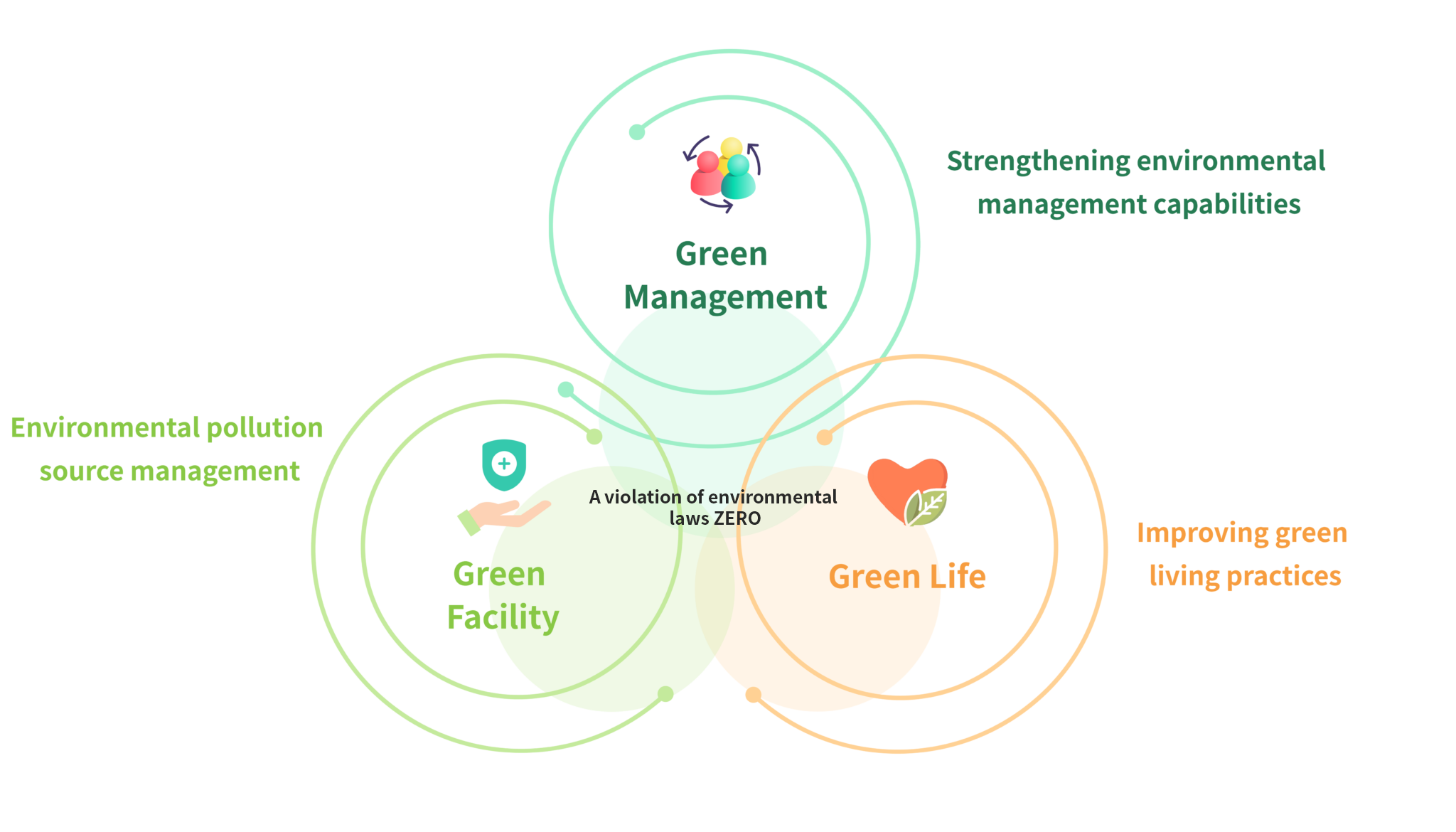

· Establishment of a company-wide integrated environmental management and response system.

· Enhancement of operation of domestic on-site environmental system

· Improving external environmental assessment credibility

The company sets environmentally friendly management goals, defines the organization, responsibilities, and procedures to achieve them, and manages them systematically by efficiently distributing human and material resources.

– Prevent potential environmental and safety accidents by cross-checking compliance with environmental laws and conducting preliminary inspections of facility operation

– Contribute to environmental improvement through appropriate investment in environmental facilities and increased interest in environmental management among organization m

– Cost reduction through energy conservation, reduction of waste emissions, etc. Enhancing objectivity in public relations through third-party evaluations of environmental management.

– Strengthening consumer marketing capabilities as an eco-friendly company.

1)Energy (electricity) usage (kwh) : 38.8% increase compared to the same period last year (as of the end of July). Causes of increase:

– Relocation of office building and expansion of office space (4,982ft2 →7,117ft2 , ’22, January~)

– Additional expansion of constant temperature and humidity chambers (1unit→2units), servers, measuring equipment, etc.

– Increase in workload and manpower

2) Resource (paper) usage (sheets) : Annual usage tally starting from 2019.

3) Separate storage of designated waste

– Implementation of separate storage of designated waste such as waste PCBs and waste lead (implemented from October 15, 2012).

4) MSDS management for hazardous chemical substances – Provide MSDS and provide training for lead, detergent, flux etc.

5) Environmental law registration management

– Registrar for the Waste Management Act, Fire Prevention, Act on Installation and Maintenance of Firefighting Facilities and Safety Management, Act on Resource Conservation and Recycling Promotion, Occupational Safety and Health Act, Act on Resource Circulation of Electrical and Electronic Products and Automobiles, and RoHS

6) Achieve T-AU RoHS compliance rate

– Achieved 96% compliance rate

7) Efforts to increase recycling rate and reduce disposal rate for T-AU prototypes

– Achieved 50% recycling rate and 15% disposal rate

8) Recovery and recycling operation of waste electronic products

© Copyright 2024 N-iTUS. All rights reserved.